1

/

of

6

My Store

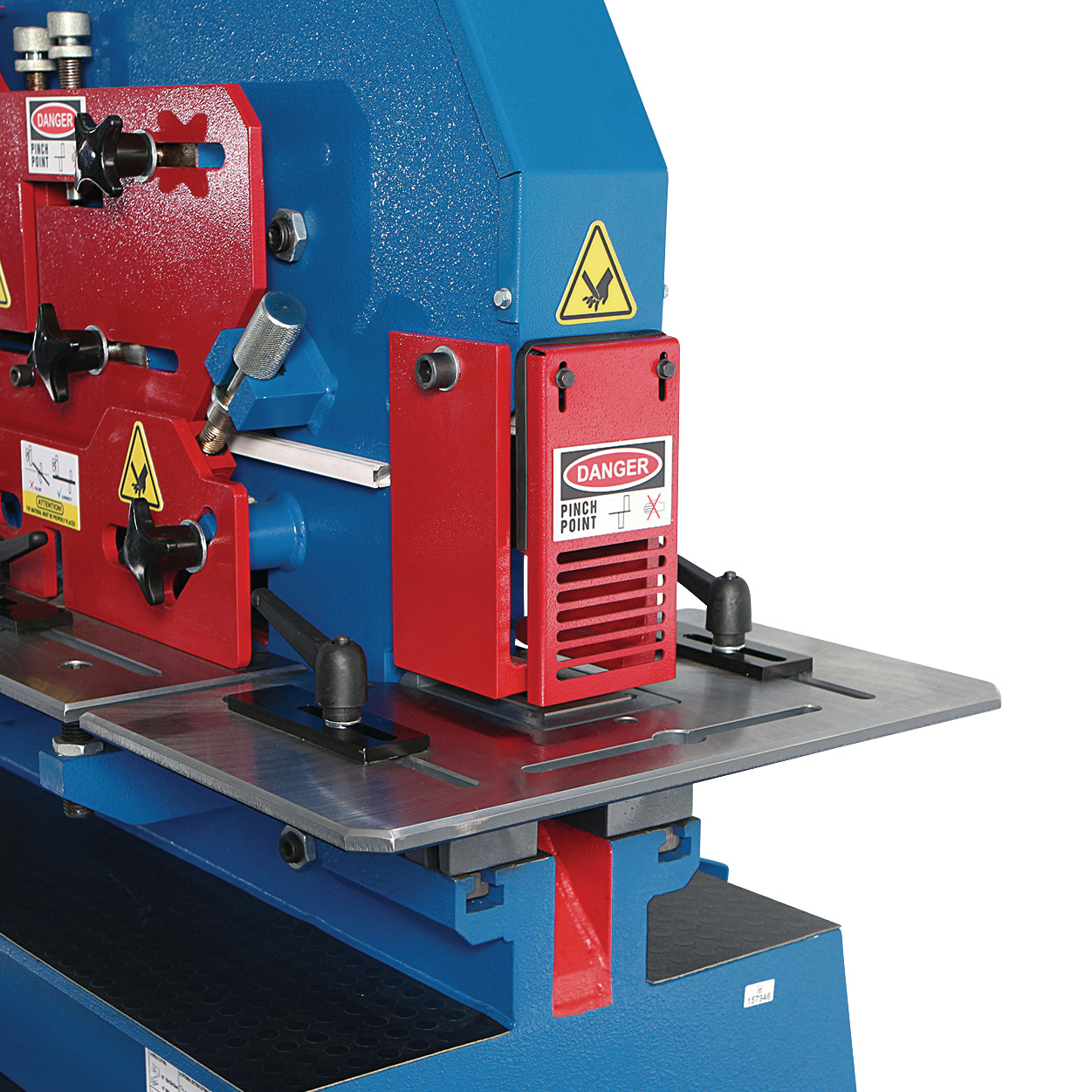

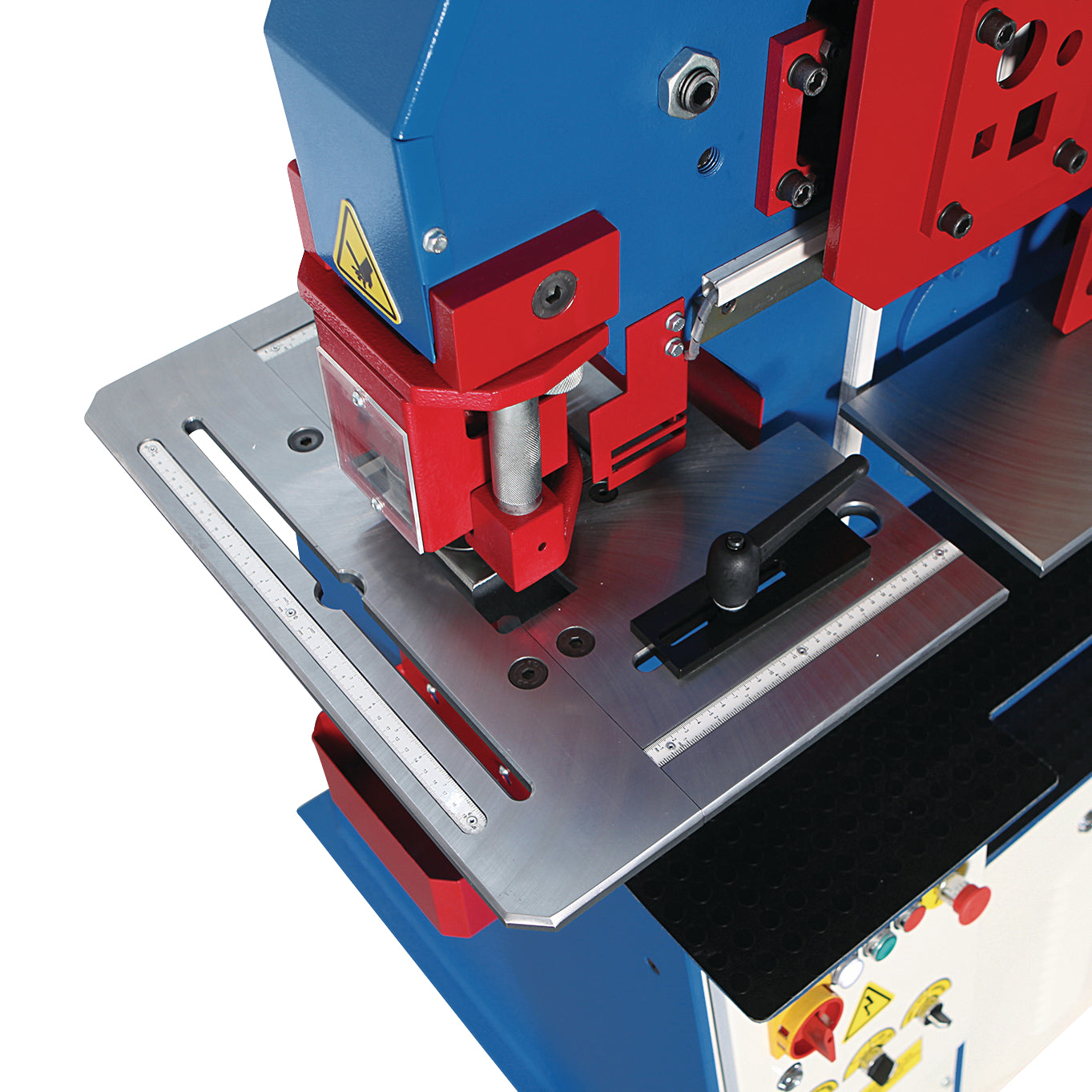

Metallkraft HPS 60 S - Hydraulic Sectional Steel Shears / Punching Machine

Metallkraft HPS 60 S - Hydraulic Sectional Steel Shears / Punching Machine

Regular price

£13,800.00 GBP

Regular price

Sale price

£13,800.00 GBP

Unit price

/

per

Couldn't load pickup availability

Share

Combined machine with up to 5 processing stations and foot operation

- Punching station, flat steel shears, angle steel shears, sectional steel shears, available with notching station starting from HPS 45S

- DS series with two working cylinders and two foot pedals for simultaneous use with punching station and sectional steel shears

- Stepless adjustment of the stroke

- Larger reach for punching station with 620 mm optional, available from HPS 55DS

- Heavy and rigid welded construction

- Standard with notching knife starting from HPS 45S

- With powerful 400 Volt motor

- V-notching knife, oversized punching device and larger throat depth for punching station available on request

- Two-stage foot pedal for inching operation

- Stamps and dies No. 1, No. 2, No. 3, No. 30, No. 45, No. 60 can be used with the standard delivery scope of the machine. Use of punch and die No. 4 and No. 80 optional (except HPS 40S)

Advantages of punching over drilling:

- High time savings - cycle times

- No chips

- No cooling

Note:

- All hydraulic sectional shears are delivered with oil

DELIVERY CONTENTS

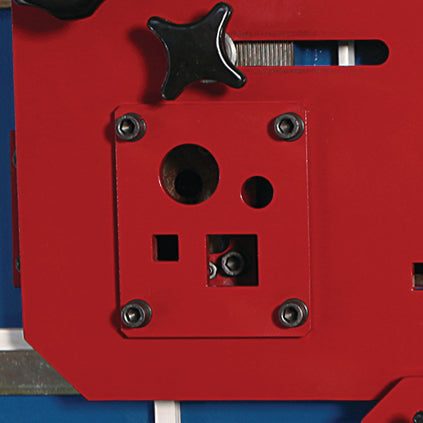

- Punching station

- Flat shear

- Angle Shear

- Section steel shears with round and square blade

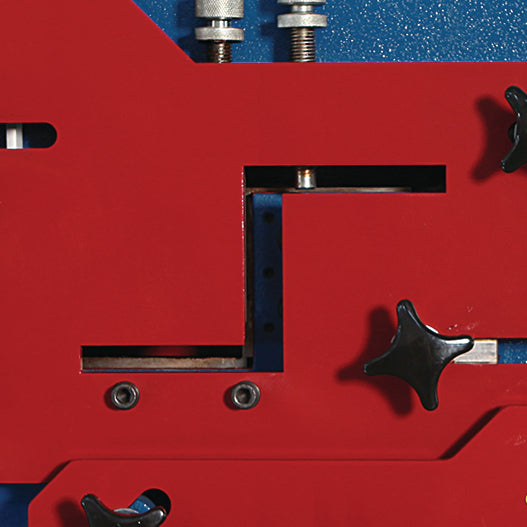

- Notching

- Stamp holder with bayonet lock

- Stamp and Die Reductions # 1, # 2, # 3, # 30, # 45, # 60

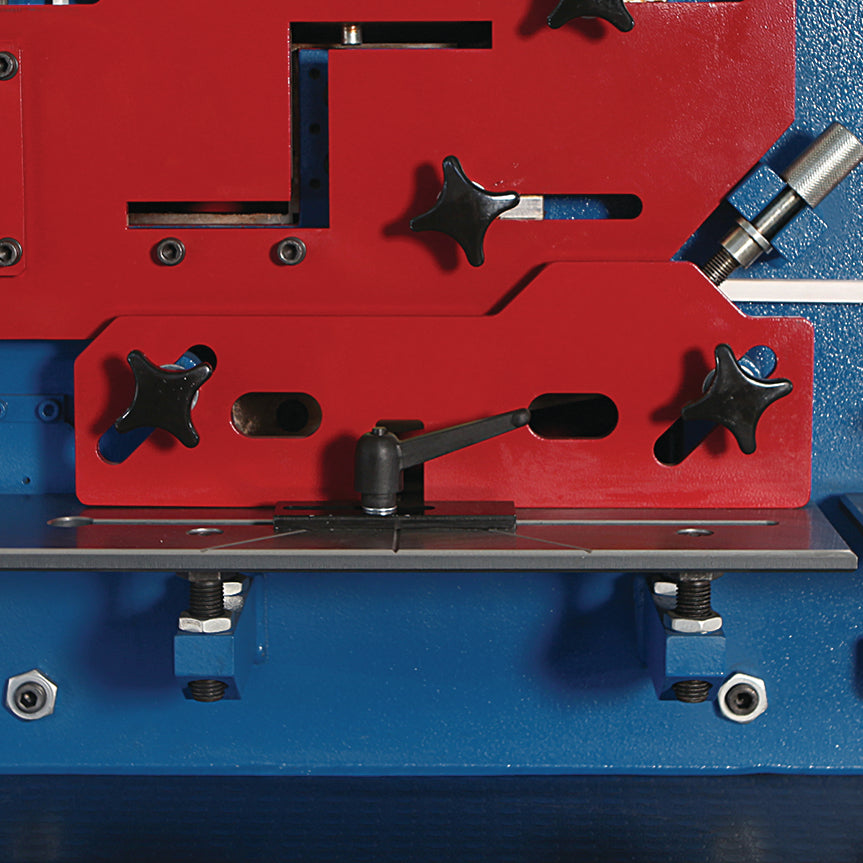

- Punch, flat steel scissors and notch with adjustable stops

- Hook wrench

- Pedal

- Hydraulic oil

| Dimensions and Weights | |||

| Length (product) approx. | 1520mm | Width/depth (product) approx. | 950mm |

| Height (product) approx. | 1780mm | Net weight approx. | 1440kg |

| Notching Station | |||

| Notching station max. material thickness | 10mm | Max. notching width | 42mm |

| Max. notching depth | 100mm | V notching tools (accessory) | 100 x 100 x 10mm |

| Electrical Data | |||

| Drive motor output | 4kW | Supply voltage | 400V |

| Mains frequency | 50Hz | ||

| Flat Steel Shears | |||

| Flat steel shears material width x max. thickness | 200 x 20mm | Flat steel shears material max. width x thickness | 300 x 15mm |

| Flat steel shears knife length | 317mm | Flat steel shears angled cut 45° max. leg length x max. thickness | 80 x 10mm |

| Flat steel shears working height | 955mm | ||

| Punching Station | |||

| Punching force | 60t | Punching station diameter x max. sheet thickness (steel 400 N/mm²) | 28 x 15mm |

| Max. punching station diameter x sheet thickness (steel 400 N/mm²) | 38 x 11mm | Punching station reach | 220mm |

| Punching station max. lift stroke | 60mm | Punching station stroke count | 25/min |

| Punching station working height | 955mm | ||

| Steel Bar Shears | |||

| Steel bar shears capacity round material | 40mm | Steel bar shears capacity square material | 40mm |

| Angled Steel Shears | |||

| Angled steel shears cutting capacity 90° L section | 120 x 120 x 12mm | Angled steel shears cutting capacity 45° L section | 70 x 10mm |

| Angled steel shears cutting capacity U-I section (accessory) | 80 x 45mm | Angled steel shears cutting capacity T section (accessory) | 80 x 9mm |

| Angled steel shears working height | 1155mm |